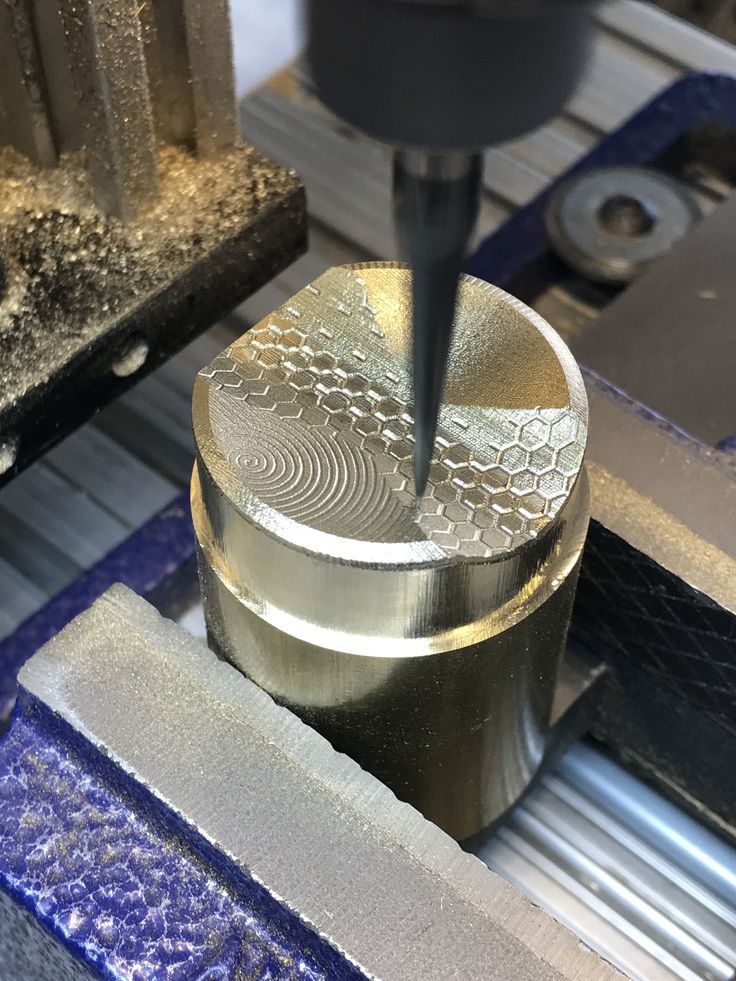

CNC Sliding Head Machining

Part Production on CNC Sliding Vending Machines – Precision, Efficiency, and Quality

Our company offers high-precision part production using CNC Sliding Vending machines. With advanced technology and an expert team, we provide high-quality and efficient solutions for all your industrial manufacturing needs. Our sliding system CNC machines enable the fast and accurate production of complex parts with various geometries.

Our Services

- High-Precision Part Production: We manufacture parts with tight tolerances using CNC Sliding Vending machines, ensuring exceptional precision.

- Complex Geometry Machining: Our sliding system CNC machines deliver excellent results when machining parts with complex geometries and intricate details.

- Production with Various Materials: We process materials such as aluminum, steel, stainless steel, plastic, and more.

- Prototyping and Mass Production: We offer flexible solutions for both single-piece prototypes and large-scale mass production.

Why CNC Sliding Vending for Part Production?

- High Efficiency: Sliding systems allow for the fast and efficient machining of numerous parts in a short time.

- Superior Precision: With CNC technology, even the most complex designs are machined with perfect accuracy.

- Time Savings: Automated systems reduce production time, enabling faster and more efficient manufacturing.

- Low Error Rate: CNC Sliding Vending machines minimize human error, ensuring highly accurate part production.

Speed up your production processes and guarantee high quality with our CNC Sliding Vending machines! Contact us for more information about part production and let us provide custom solutions for your needs

| Standards | CNC Milling | CNC Turning |

|---|---|---|

| Maximum Part Size | 7500×3400×1200 mm 295×133.8×47 in. |

200×500 mm 7.9×19.7 in. |

| Minimum Part Size | 3.5×3.5 mm 0.13×0.13 in. |

2×2 mm 0.079×0.079 in. |

| Minimum Feature Size | Φ 0.50 mm Φ 0.00197 in. |

Φ 0.50 mm Φ 0.00197 in. |

| Standard Tolerances | Metals: ISO 2768-m Plastics: ISO 2768-c |

Metals: ISO 2768-m Plastics: ISO 2768-c |

| Linear Dimension | +/- 0.01 mm +/- 0.0004 in. |

+/- 0.01 mm +/- 0.0004 in. |

| Hole Diameters (Not Reamed) |

+/- 0.01 mm +/- 0.0004 in. |

+/- 0.01 mm +/- 0.0004 in. |

| Shaft Diameters | +/- 0.01 mm +/- 0.0004 in. |

+/- 0.01 mm +/- 0.0004 in. |

| Edge Condition |

Sharp corners will be removed in the form of a chamfer or radius. The size of the chamfer, or resulting radii, must be indicated on the drawing. |

|

| Threads and Tapped Holes |

Diameter: Φ 1.5-5 mm, depth: 3×diameter Diameter: Φ 5 mm or more, depth: 4-6×diameter |

Diameter: Φ 1.5-5 mm, depth: 3×diameter Diameter: Φ 5 mm or more, depth: 4-6×diameter |

| Arm Tech CNC can manufacture threads to any specification and size required by our customers. | ||

| Text |

Minimum width of 0.5 mm, depth of 0.1 mm Arm Tech CNC can utilize CNC engraving or laser carving to create standard text according to customers’ requirements. |

Arm Tech CNC can employ laser marking to create standard text on CNC turned parts. |

Our company specializes in plastic injection, sheet metal forming, CNC milling (3, 4, 5 axis), and CNC turning, offering innovative and reliable manufacturing solutions. Since our establishment, we have been committed to delivering high-quality products and services, making a difference in our industry.

Contact Info

info@armtechcnc.com

Phone

+90 541 801 91 10

Copyright © 2025 ARM Tech CNC. All rights reserved. – Digitolye Web Design