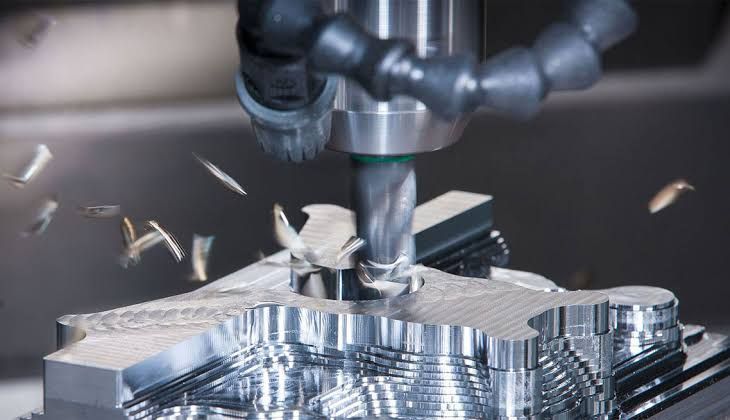

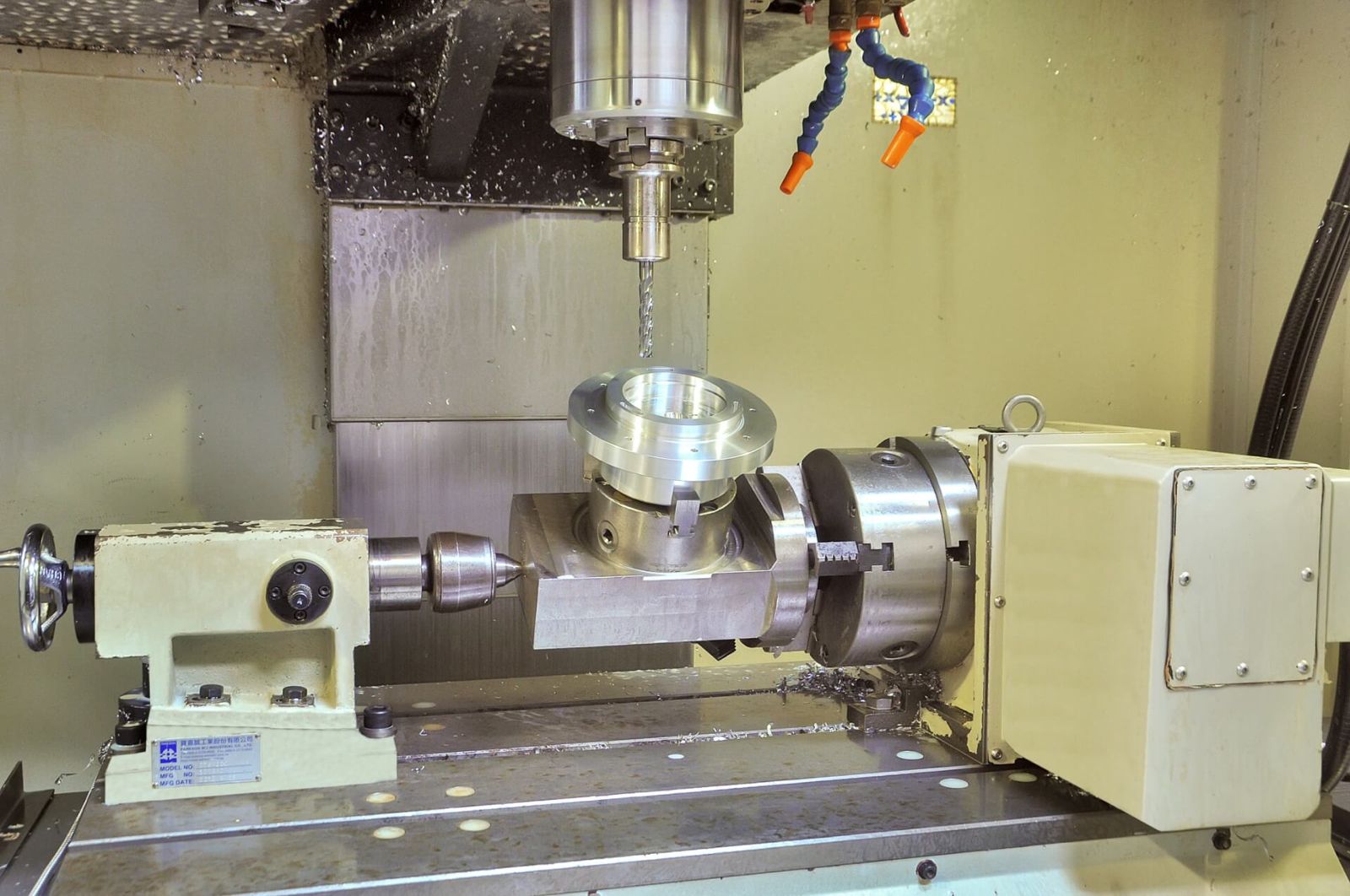

CNC Milling(3-4 and 5 axis)

Your Trusted Partner in CNC Milling (3, 4, 5 Axis) and Precision Manufacturing

Our company offers high-quality production solutions with precision machining through 3, 4, and 5-axis CNC milling technology. With modern equipment and a professional team, we deliver results that exceed customer expectations.

Our Services

- Precision Machining: We manufacture complex and detailed parts with exceptional accuracy using 3, 4, and 5-axis CNC machines.

- Prototype Production: We provide fast and reliable prototyping solutions to support your product development processes.

- Mass Production: We deliver efficient production services for small and large-scale manufacturing needs.

- Material Versatility: We work with aluminum, steel, stainless steel, plastic, and other materials.

Why Choose Us?

- Advanced Technology: Our modern CNC machines ensure high precision and enable the successful machining of even the most complex designs.

- Quality Assurance: We inspect and deliver our products in compliance with international quality standards.

- On-Time Delivery: We complete your projects within the scheduled timeframe, accelerating your processes.

- Custom Solutions: We develop tailored production solutions to meet your specific requirements.

If you’re looking for precision and quality in machining, you’ve come to the right place! Contact us for your CNC milling needs, and let us bring your projects to life.

| Standards | CNC Milling | CNC Turning |

|---|---|---|

| Maximum Part Size | 7500×3400×1200 mm 295×133.8×47 in. |

200×500 mm 7.9×19.7 in. |

| Minimum Part Size | 3.5×3.5 mm 0.13×0.13 in. |

2×2 mm 0.079×0.079 in. |

| Minimum Feature Size | Φ 0.50 mm Φ 0.00197 in. |

Φ 0.50 mm Φ 0.00197 in. |

| Standard Tolerances | Metals: ISO 2768-m Plastics: ISO 2768-c |

Metals: ISO 2768-m Plastics: ISO 2768-c |

| Linear Dimension | +/- 0.01 mm +/- 0.0004 in. |

+/- 0.01 mm +/- 0.0004 in. |

| Hole Diameters (Not Reamed) |

+/- 0.01 mm +/- 0.0004 in. |

+/- 0.01 mm +/- 0.0004 in. |

| Shaft Diameters | +/- 0.01 mm +/- 0.0004 in. |

+/- 0.01 mm +/- 0.0004 in. |

| Edge Condition |

Sharp corners will be removed in the form of a chamfer or radius. The size of the chamfer, or resulting radii, must be indicated on the drawing. |

|

| Threads and Tapped Holes |

Diameter: Φ 1.5-5 mm, depth: 3×diameter Diameter: Φ 5 mm or more, depth: 4-6×diameter |

Diameter: Φ 1.5-5 mm, depth: 3×diameter Diameter: Φ 5 mm or more, depth: 4-6×diameter |

| Arm Tech CNC can manufacture threads to any specification and size required by our customers. | ||

| Text |

Minimum width of 0.5 mm, depth of 0.1 mm Arm Tech CNC can utilize CNC engraving or laser carving to create standard text according to customers’ requirements. |

Arm Tech CNC can employ laser marking to create standard text on CNC turned parts. |

Our company specializes in plastic injection, sheet metal forming, CNC milling (3, 4, 5 axis), and CNC turning, offering innovative and reliable manufacturing solutions. Since our establishment, we have been committed to delivering high-quality products and services, making a difference in our industry.

Contact Info

info@armtechcnc.com

Phone

+90 541 801 91 10

Copyright © 2025 ARM Tech CNC. All rights reserved. – Digitolye Web Design